Oil spill solutions

Absorbent methods for effective cleanup

When oil spills occur, fast, sustainable action is critical. T1 Solutions offers advanced, eco-conscious oil spill solutions designed for real-world impact. Whether you’re cleaning oil spills in the ocean or on land, our reusable absorbent technology offers both environmental and economic advantages, making cleanup efficient and responsible.

What is an Oil Spill?

Two main types of oil spillage.

An oil spill refers to the accidental release of petroleum or derivatives into the environment, causing serious ecological damage. Solutions to oil spills vary depending on the location and scale. There are two primary types: marine oil spills and land oil spills.

Marine oil spills.

Marine oil spills occur in open seas or nearshore areas. Offshore accidents, such as those from tankers or drilling rigs, are classified as “at sea,” while those near harbors or coasts are “on shore.” Famous cases include the Deepwater Horizon spill (Gulf of Mexico) and Exxon Valdez (Alaska). These large-scale disasters require strategic oil spill containment and cleanup methods, including skimmers, booms, and high-capacity oil absorbent materials.

Land oil spills.

Land oil spills typically occur in industrial zones, pipelines, or during transportation accidents. While generally smaller in scale, they can severely contaminate soil and water supplies. Prompt oil spill remediation is essential to limit damage and meet environmental compliance.

Our oil spill cleanup equipment

T1 Solutions is an innovative SME and benefit company whose mission is to protect the environment with greater concern for the marine ecosystem through the prevention and control of oil spills occur-ring in the water and through the use of FoamFlex in all its declinations for the benefit of all stake-holders.

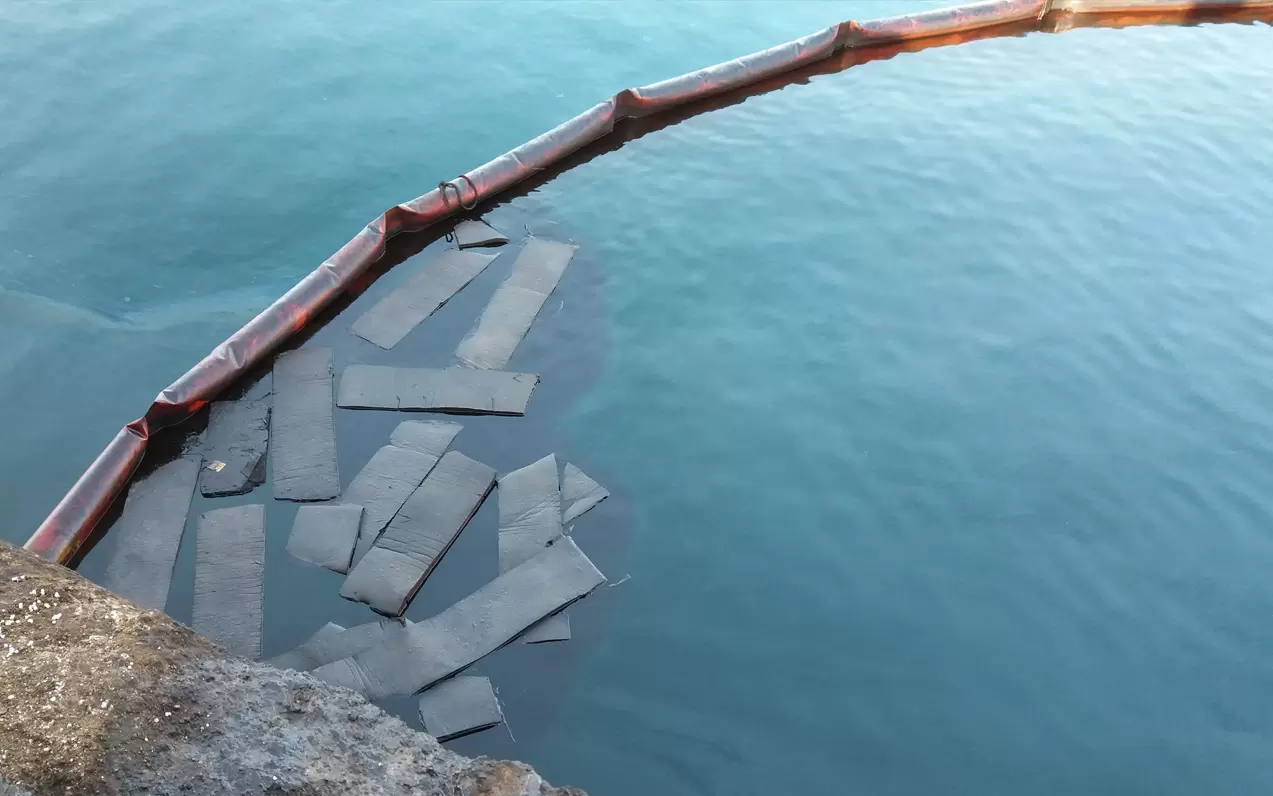

Oil spill booms

Oil spill booms are essential containment tools used to limit the spread of oil on water surfaces. T1’s FoamFlex-enhanced booms combine high retention with ease of deployment, making them reliable booms for oil spills in open waters and nearshore applications.

Oil absorbent pads

Designed for precision absorption, oil absorbent pads are perfect for surface spills and small-scale remediation. Their high saturation speed makes them suitable for rapid deployment in emergency scenarios. These pads are part of our broader range of oil absorbent products.

Oil absorbent mops

Used for manual application, oil spill mops are practical tools to clean confined or hard-to-reach areas. They are lightweight, effective, and reusable—specially designed for targeted intervention in oil-contaminated zones.

Oil spill kits

Oil spill kits bundle essential absorbent products to address spills of different sizes quickly and effectively. T1 kits include items like absorbent pads, socks, gloves, and collection bags. Our oil spill kits are available in sizes adapted to both marine and industrial use.

Oil absorbent socks

Ideal for indoor and industrial use, oil absorbent socks are flexible and mold to surfaces, creating an effective barrier to prevent spreading. These sorbent socks are especially useful in areas where precision containment is required.

Oil absorbent mats

Oil absorbent mats are ideal for both marine and land-based interventions. Made from patented open-cell polyurethane foam, these reusable mats selectively absorb hydrocarbons while repelling water. Each standard mat can absorb up to 6,000 kg of oil per 1 kg of material, significantly increasing operational efficiency in both marine and land-based cleanups. T1’s oil absorbent mats are engineered for high efficiency in varied environments.

Why choose T1 Solutions for oil spill response?

T1 Solutions combines patented technology with proven environmental and economic impact. Our FoamFlex products are certified by international authorities and tested in real-world scenarios, offering up to 93% cost savings and 99.8% waste reduction. Recognized by the European Commission’s Seal of Excellence and named a Top 10 innovation in Oil & Gas by OGTC Aberdeen, our patented FoamFlex technology is reshaping industry standards. Trusted by ports, coast guards, and industrial operators worldwide, we redefine how oil spill remediation is done.

Quick benefits of FoamFlex solutions:

- Absorbs up to 30 times its weight in oil, with 1 kg capable of absorbing up to 6,000 kg of oil

- Reusable up to 200 times through a simple wringing process, enabling significant waste reduction

- Selectively absorbs oil while repelling water (less than 5% water uptake), ensuring efficient, water-free oil recovery

- Reduces clean-up costs by up to 93% due to high absorption capacity and reusability

- Minimizes waste generation and lowers overall carbon footprint

- Fast absorption kinetics for rapid saturation and deployment in emergency scenarios

- Compact and lightweight design for easy storage and rapid response

Ways to clean up an oil spill

Once the right equipment is in place, it’s crucial to choose the correct clean-up method depending on the spill’s scope and location. There are multiple oil spill cleanup methods, depending on the environment and severity. Whether cleaning oil spills in a marina or addressing large spills in the ocean, choosing the right method is crucial.

Small marine oil spills

In ports, marinas, or nearshore areas, small oil spills are typically handled manually. Using absorbents like FoamFlex, responders can quickly clean surface spills without heavy machinery. With less than 5% water uptake, FoamFlex enables clean, water-free oil recovery, minimizing secondary waste and treatment. The product floats, absorbs instantly, and can be reused up to 200 times.

Large oil spills

For large-scale spills, such as those from tankers or offshore rigs, a combination of containment booms, skimmers, and high-capacity absorbents is required. FoamFlex can be deployed in bulk, recovers oil with minimal water content, and reduces waste and costs by up to 93%. Its high absorption kinetics allow complete saturation within minutes, enabling swift action in high-pressure emergency scenarios.

How long does it take to clean up an oil spill?

The time needed depends on spill size, location, and environmental conditions. Small spills may take a few hours with the right oil spill absorbent tools. Large offshore incidents can take weeks or even months. The use of FoamFlex significantly reduces intervention time.

Oil spill and prevention

Preventing oil spills requires proactive systems, employee training, and access to proper containment tools. Some key practices include real-time monitoring systems, regularly updated response protocols, and the installation of pre-positioned booms and spill kits in high-risk areas. T1 Solutions partners with ports and industries to provide effective oil spill prevention strategies that comply with global environmental regulations.

Ready to rethink your oil spill response strategy? Discover how T1 Solutions can help you clean more efficiently, reduce waste, and protect the environment—without compromising on performance. Explore our full range of oil spill solutions!

What is the best solution for an oil spill?

The best solution combines oil spill containment and high-efficiency absorbents like FoamFlex, tailored to the size and location of the spill.

What is FoamFlex and how does it work?

FoamFlex is a patented oil spill absorbent made of oleophilic, hydrophobic polyurethane foam that can absorb hydrocarbons up to 30 times its weight and be reused up to 200 times

How many times can FoamFlex be reused?

Up to 200 times, thanks to its resistance and simple wringing system that separates oil without water contamination.

Which are the main causes of the oil spills?

Operational errors, equipment failure, accidents during oil transport, and natural disasters are among the main causes of oil spills.

What are the enviromental risks if an oil spill isn’t cleaned properly?

Long-term pollution of marine ecosystems, water toxicity, loss of biodiversity, and severe economic impacts on fishing and tourism industries.